|

Portable CMM and 3D laser scanning products are highly recommended as an integral part of the process of inspection, quality controls, alignment and reverse engineering

|

Laser radar is the right product for large volume applications with non contact measurement. Providing high precision help to reduce manufacturing cost and improve quality

|

|

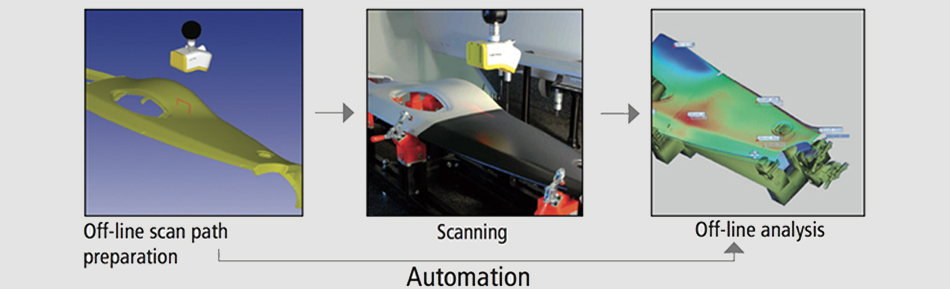

| X-ray and CT Inspections | ||

|

X-ray and Computed Tomography (CT) inspection systems that get the inside picture of complex industrial parts, by looking into the internal structure. The CT capability is used to qualify and quantify any inner or outer dimension in a smooth, non-destructive process

|

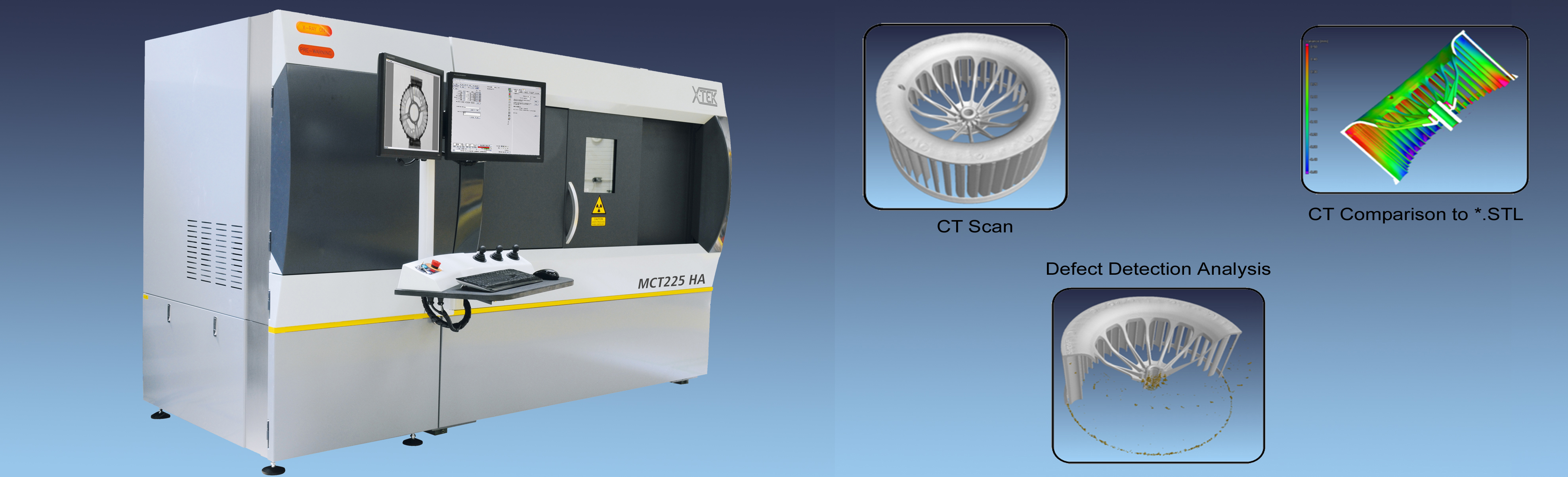

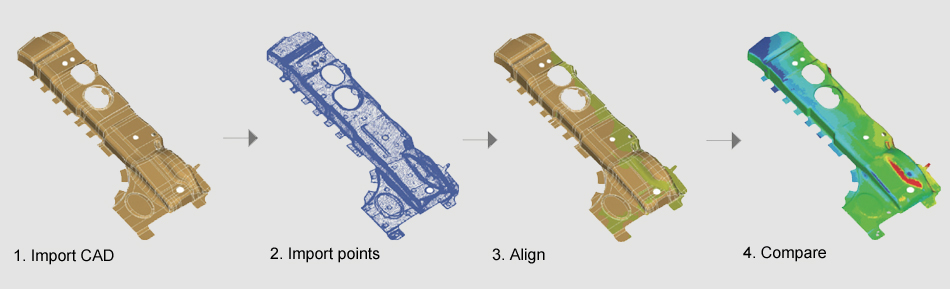

Laser scanners are used with CMMs, articulated arms, optical CMMs or even robots. The resulting digital copy forms the backbone of a powerful digital inspection process that streamlines inspection processes, reduces time to market and cuts development costs.

|

|

| Coordinate Measuring Machines | Motion Measurement and Robotic | |

|

Designed and manufactured using only the highest quality materials, they carry a heritage of over 45 years experience and expertise. LK CMMs deliver the ability to perform dimensional, positional and surface measurement in a single system. The only 10 years original accuracy guaranty in the market.

|

Adaptive Robot Control activates a closed metrology-driven feedback loop that firmly increases the precision of industrial robots. Regardless whether robots are deployed for machining, inspection, applying beads or manipulating objects, roboting tasks are consequently executed with 0.1mm absolute accuracy.

|

|

| CAMIO Software | Focus Software | |

|

Proven in the most challenging application environments CAMIO is the CMM software of choice for many of the world’s largest manufacturers. By leveraging the productivity benefits of CAMIO, manufacturers can focus on accelerating lead times and improving product quality while reducing costs.

|

Focus Inspection is today’s reference for point cloud inspection. It manages acquired point clouds and performs part-to-CAD comparison and advanced feature inspection. The software covers a wide range of inspection applications and offers stunning performance, an intuitive user interface, and standard macro functionality to automate the entire inspection process.

|